Home > Company Introduction

Company Overview

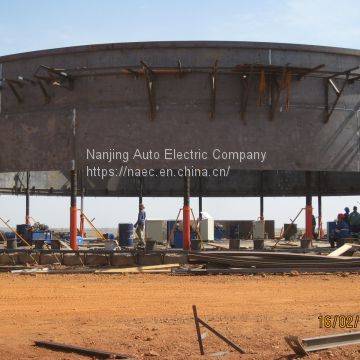

Nanjing Auto Electric Co., Ltd (NAEC) was established in 2001, taking promoting "Lean Fabrication to Global Energy Engineering Industry" as its mission, NAEC's core business is to provide Lean-fabrication One-stop Solution to energy engineering contractors and fabricators. With advanced innovation ability and continuous integration of new technology & processes, NAEC's solution ensure its users high quality and efficient fabrication, and make itself become worldwide clients' most preferred partner. Our Strategic Clients are EPC companies, Contractors or Fabricators in Onshore Oil & Gas Exploration, Transportation, Storage, Refinery & Chemical EPC companies, Contractors, Fabricators or Equipment Manufacturers in Offshore Oil & Gas Exploration, Treatment, Transportation & Storage EPC companies, Contractors or Fabricators in Nuclear Power, Wind Power, or Thermal Power Various Energy Engineering Equipment Manufacturers We provide Lean-fabrication One-stop Solution for Energy Engineering EPC Companies/ Contractors/ Fabricators, Based on Following Systems: A. NAEC Lean-fabrication Mode B. NAEC Lean-fabrication Management System C. NAEC Lean-fabrication Production System NAEC Lean-fabrication One-stop Solution can help engineering fabrication operators to solve project problems. It can organize fabrication production and ensure the final delivery in good quality and on time.

-

ManufacturerBusiness Type

-

2001Year Established

-

YesOverseas Office

-

US$5 Million - US$10 MillionAnnual Export Value

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

11-20 People Sales Staff

-

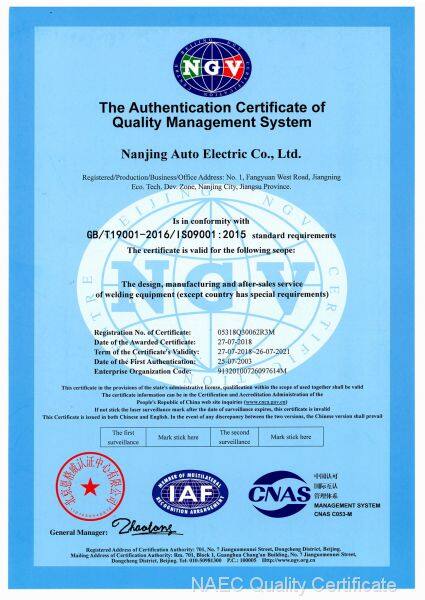

ISO9001, Others Product Certifications

-

US$5 Million - US$10 Million Annual Export Value

-

Southeast Asia, Mid East Main Markets

-

Yes Overseas Office

-

Petrochemical Refining Main Industry

Our Certifications

Showcasing our professional qualifications and recognized industry certifications.